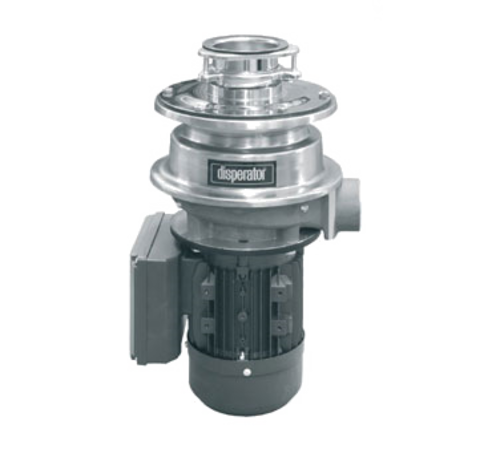

UPster H500 GiO AC pass-through dishwasher with integrated GiO reverse osmosis water treatment unit for spot free washing and hygienically flawless washing results, incorporating Air Concept integrated air management unit with built-in, self-cleaning heat recovery unit. Machine constructed throughout in type 304 (1.4301) high grade stainless steel and with full external stainless steel cladding. Additional features include pressed tank with large radius coved corners, double wall construction for excellent sound and heat insulation, and sloped internal upper wash tank surfaces to prevent dripping onto clean items.

Up to 720 dinner plates per hour

(Dependent upon electrical and water temperature connections)

Dimensions: 635 (w) x 750 (d) x 2140 mm (h) (Top of AC unit)

Passing height 440 mm

Basket size 500 mm x 500 mm

Available 400/50/3phase

Capacity : 40 racks per hour

10ºC cold fill 3 phase : 9.83 kW

Product listed in WRAS water fittings and materials directory. Certificate No. 1607063. This appliance has a Fluid Category 5 backflow prevention device built-in. *Suitable for water connection up to 18 degrees clark, addtional water treatment will be required above this hardness.

Provided with the following features: –

90/150/240 second programmes

Water connection 1 x 22 mm ¾” BSP

Suitable for a softened cold water supply

Water supply pressure 1-5 bar

Minimum flow rate 8lt/min

Tank fill capacity 22lt

Final rinse consumption 2.6lt/basket

Waste connection 2 x 40 mm Ø standing waste

Wash pump motor rating 0.75 kW

Detergent and rinse dosing aid pump incorporated

Hose and cable connection kit supplied

Drain pump and rinse booster pump fitted as standard

Soft start feature on wash pump motor

Rotating upper and lower rinse and wash arms

Aqua-stop system for water leak detection

Aktiv plus double filtration of wash water

Perforated covers over wash tank

Internal basket guides adjustable on site for corner or straight operation

MIKE 2 Infrared interface for exchange of data services

Touch sensitive control (no switches)

Self-cleaning cycle following drain down

Two (2) finger type plate racks

One (1) open type cup/bowl rack

Two (2) eight compartment cutlery racks

Note:

GiO module overall dimensions 140mm (w) x 550 mm (d) x 600 mm (h)

Feed water temperature to be not less than 1ºC and not more than 30ºC.

Maximum hardness of the untreated water not to exceed 24° Clarke (343ppm)

Conductivity of the untreated feed water to be no more than 1000 NS/cm

Purity level of the treated water in the region of 98%

Water filter, stop-valve, non-return check valve, pressure reducing valve and manometer included as part of the connection kit.

Supplied filter to be changed, interval dependent on water quality.

GiO-Module mounted to one side of the machine.

Incorporating Point Air Concept integrated air management unit with built-in, self-cleaning heat recovery unit.

Machine overall height with Air Concept fitted will be 2140mm.

Machine requires a cold water fill only.

Machine equipped with built-in self-cleaning nozzles.

No additional water need for the self-cleaning process.

Exhaust air extraction program extension time will be 30 seconds.

Reduction in radiated heat transmitted from the machine will be 1.3kW.

Exhaust air temperature with incoming water at 12°C will be 25°C.

Reduction of steam volume discharged into the wash-up area will be 80%.

Reduction in the connected load of the washing machine will be 1.5kW.

Stainless steel heat recovery unit for GiO machine.

A minimum of 20-25 air changes per hour required within the dish wash area for efficient operation of the AC unit.

(Ref: UPster H500 GiO AC)

Reviews

There are no reviews yet.